Product Description

| Description: | Brake Hub |

| Model: | Sany 4250 |

| Part No.: | 13145712571A005 |

| Brand: | ZHONGPEI |

| Warranty: | 6 Months |

| Application: | Truck |

| Package: | Carton Box |

One -station purchasing

Occupy an area of 50, 000 square meters, 20 warehouses with over 700 members…

Supporting with over 100, 000 kinds of spare parts, which make us always offer our customers satisfied service, especially timely deliver and variety kinds of auto parts

1: 25 years’ experience in auto parts.

2: No. 1 auto parts supplier in China Brand vehicles.

3: Auto parts on light, medium and heavy truck, bus, pick up.

4: Supply Engine/Gearbox assy and all Engine/Gearbox/Chassis/Body spare parts.

Chinese brand vehicles’ spare parts available…

| JAC SERIES

JAC1571,JAC1571,JAC1030,JAC1035,JAC1040,JAC1045,JAC1048,JAC1061,JAC1063,JAC1083,JAC3045,JAC3048,JAC3072,JAC3090,JAC-SWORD,JAC-GALLOP,ReFine,JAC-BUS(HK/HFC),JAC-forklifts,JAC-PICK… |

| FOTON/FORLAND/BAW SERIES

BJ1571,BJ6486/88, BJ1571,BJ1571,BJ1036,BJ1039,BJ1043,BJ1046,BJ1049(OLLIN),BJ1069(OLLIN),BJ1089,BJ3042,BJ3043,BJ3052,BJ3062,BJ3072,AUMAN,BAW1030,BAW1040,BAW1044,BAW1048^ |

| JMC/ISUZU SERIES

JMC1571,JMC1030,JMC1032,JMC1040,JMC1042,NHR,NKR,100P,600P,700P^ |

| XIHU (WEST LAKE) DIS.FENG SERIES

EQ1030,EQ1032,EQ1040,EQ1044,EQ1045,EQ1071,EQ1081,EQ3060,EQ3061,EQ3092,DFL-KINLAND,DFA-BUS^ |

| CZPT SERIES

STEYR,STEYR KING,NEW-HUANGHE,HOWO,HOWO-A7,SITRAK-T7H,Golden Prince,HOKA,HAOYUN,HOWO -LIGHT TRUCK,MINE TRUCK,Golden Prince^ |

| CZPT SERIES

CA1571,CA1031,CA1041,CA1047,CA1051,CA1061,CA1081,J4,J4Q,J5K,J5M,J5P,J5Q,J6^ |

| YUXIHU (WEST LAKE) DIS. SERIES

NJ1571,NJ1026,NJ1571,NJ1030,NJ1035,NJ1038,NJ1040,NJ1042,NJ1043,NJ1062,NJ1063^ |

| BUS SERIES

KING LONG(XMQ),GOLDEN DRAGON(XML),HIGER(KLQ),YUTONG(ZK),ZHONG TONG(LCK),YOUNG MAN(JNP),HENG TONG(CKZ),SHAOLIN(SLG),XIHU (WEST LAKE) DIS.,SHENLONG(SLK),ANKAI(HFF),FOTON O-V(BJ),HUANGHAI(DD),ZONDA(YCK)^ |

| OTHER SERIES

ZheJiang -F2000, ZheJiang -F3000,SAIC-IVECO XIHU (WEST LAKE) DIS.N,CAMC GREAT WALL(CC),ZXIHU (WEST LAKE) DIS.(BQ),JINBEI(SY),DADI AUTO(BDD),XINKAI(HXK),TIANMA(KZ),GONOW,HAFEI,CHANA,CHANGHE,XIHU (WEST LAKE) DIS.,CHERY,GEELY,BYD^ |

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do I diagnose and address noise issues associated with a malfunctioning axle hub?

Diagnosing and addressing noise issues associated with a malfunctioning axle hub requires a systematic approach to identify the root cause and take appropriate corrective measures. Here’s a detailed explanation of the diagnostic process and steps to address the problem:

1. Identify the Noise:

The first step is to identify the specific noise associated with the malfunctioning axle hub. Pay attention to the type and characteristics of the noise, such as grinding, growling, clicking, or humming. Note when the noise occurs, whether it’s during acceleration, deceleration, or while turning. This initial identification can help narrow down the possible causes.

2. Inspect the Axle Hub:

Visually inspect the axle hub for any signs of damage or wear. Look for cracks, corrosion, or loose components. Check if there is any leaking grease around the hub, as it can indicate bearing failure. A thorough inspection can provide valuable clues about the condition of the axle hub.

3. Perform a Road Test:

Take the vehicle for a road test to observe the noise and its behavior under different driving conditions. Pay attention to any changes in the noise when making turns, accelerating, or braking. Note whether the noise gets louder or changes in pitch. This can help in further narrowing down the issue.

4. Jack up the Vehicle:

If the noise persists and is suspected to be coming from the axle hub, jack up the vehicle and secure it with jack stands. Rotate the wheel associated with the suspected axle hub and listen for any abnormal noise or roughness. Try to wiggle the wheel by hand to check for excessive play or looseness, which can indicate a problem with the hub assembly.

5. Check Wheel Bearings:

A common cause of noise issues in axle hubs is worn-out or damaged wheel bearings. To check the wheel bearings, grasp the tire at the 12 o’clock and 6 o’clock positions and attempt to rock it back and forth. Excessive movement or play indicates a potential problem with the wheel bearings. Additionally, spin the wheel and listen for any grinding or rumbling noises, which can also be indicative of bearing issues.

6. Addressing the Issue:

If a malfunctioning axle hub is identified as the source of the noise, the following steps can be taken to address the problem:

- Replacement: If the axle hub is severely damaged or the bearings are worn out, replacing the entire hub assembly is often recommended. This ensures proper fitment, bearing integrity, and overall reliability. Consult the vehicle’s service manual or seek professional assistance for the correct replacement procedure.

- Bearing Replacement: In some cases, it may be possible to replace the wheel bearings within the axle hub if they are the sole source of the noise issue. This requires specialized tools and expertise, so it is advisable to consult a qualified mechanic for bearing replacement.

- Additional Repairs: Depending on the severity of the issue, it may be necessary to address other related components. This can include replacing damaged CV joints, inspecting and replacing worn brake components, or addressing any other issues identified during the diagnostic process.

7. Post-Repair Verification:

After addressing the noise issue by repairing or replacing the malfunctioning axle hub, take the vehicle for a test drive to verify that the noise is eliminated. Ensure that the vehicle operates smoothly, and there are no abnormal vibrations or noises coming from the axle hub during different driving conditions.

It’s important to note that diagnosing and addressing noise issues associated with a malfunctioning axle hub can be complex, and it may require the expertise of a qualified mechanic. If you’re uncomfortable performing the diagnostics and repairs yourself, it’s advisable to seek professional assistance to ensure an accurate diagnosis and proper resolution of the issue.

In summary, diagnosing and addressing noise issues associated with a malfunctioning axle hub involves identifying the noise, inspecting the hub, performing a road test, checking wheel bearings, and taking appropriate repair or replacement measures. Following a systematic approach and seeking professional help when needed can help resolve the noise issue and ensure the safe operation of the vehicle.

Are there aftermarket axle hubs available with enhanced durability or performance features?

Yes, there are aftermarket axle hubs available with enhanced durability or performance features. Aftermarket parts are components that are produced by manufacturers other than the original equipment manufacturer (OEM) of the vehicle. These aftermarket axle hubs are designed to provide improved durability, performance, or other specialized features compared to the stock OEM axle hubs. Here’s a detailed explanation:

- Durability enhancements: Aftermarket axle hubs may incorporate design improvements or use materials that enhance their durability and longevity. These enhancements can include reinforced bearing housings, stronger wheel studs, improved seals and gaskets, or upgraded materials that better withstand heavy loads, extreme temperatures, or harsh driving conditions. The goal is to provide a more robust and long-lasting axle hub solution.

- Performance features: Some aftermarket axle hubs are designed to offer enhanced performance characteristics. These performance features can include better heat dissipation properties, reduced rotational friction, or improved weight distribution. Performance-oriented axle hubs may also be engineered to provide more precise wheel alignment, improved handling, or reduced unsprung weight, which can contribute to overall vehicle performance.

- Specialized applications: In addition to durability and performance enhancements, aftermarket axle hubs may be available for specialized applications. For example, there are aftermarket axle hubs designed specifically for off-road vehicles, heavy-duty towing, or high-performance sports cars. These specialized axle hubs may have features such as increased load-bearing capacity, improved water and debris resistance, or compatibility with upgraded braking systems.

- Brands and manufacturers: The aftermarket industry offers a wide range of options from various brands and manufacturers. Some aftermarket companies specialize in producing high-quality replacement parts, including axle hubs, that are designed to meet or exceed OEM standards. These aftermarket brands may have a reputation for providing durable and high-performance products, and they often offer warranties to back up their claims.

- Research and compatibility: When considering aftermarket axle hubs with enhanced durability or performance features, it is essential to conduct thorough research. Look for reputable aftermarket brands known for their quality and reliability. Additionally, ensure compatibility with your specific vehicle make, model, and year. Most aftermarket manufacturers provide compatibility information or have online resources to help you select the correct axle hub for your vehicle.

It’s worth noting that while aftermarket axle hubs can offer enhanced durability or performance features, not all aftermarket parts are created equal. The quality and performance of aftermarket axle hubs can vary depending on the manufacturer and brand. It’s advisable to choose reputable aftermarket brands that have a track record of producing reliable and high-quality components. Consulting with automotive professionals or enthusiasts and reading customer reviews can also provide valuable insights when selecting aftermarket axle hubs.

In summary, aftermarket axle hubs with enhanced durability or performance features are available. These aftermarket options may incorporate design improvements, specialized materials, or performance-oriented features to offer increased durability, improved performance, or compatibility with specialized applications. Conducting thorough research and selecting reputable aftermarket brands can help ensure the quality and compatibility of the aftermarket axle hubs for your vehicle.

Are there any recalls or common issues associated with specific axle hub models?

Recalls and common issues can occur with specific axle hub models due to manufacturing defects, design flaws, or other factors. Here’s a detailed explanation:

It’s important to note that specific recalls and common issues can vary depending on the make, model, and year of the vehicle, as well as the specific axle hub manufacturer. Manufacturers and regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) monitor and address safety concerns related to axle hubs through recalls and investigations.

Recalls are typically initiated by the vehicle manufacturer or the axle hub manufacturer in response to identified safety defects or non-compliance with safety standards. Recalls aim to address the issues and rectify any potential safety risks associated with the axle hub models. They may involve inspections, repairs, or replacements of the affected components.

To determine if there are any recalls or common issues associated with specific axle hub models, it is recommended to check the following sources:

- Manufacturer’s Website: Visit the official website of the vehicle manufacturer or the axle hub manufacturer. They often provide information on recalls, technical service bulletins (TSBs), and common issues related to their products. Look for any relevant information specific to the axle hub models in question.

- NHTSA Website: The NHTSA maintains a comprehensive database of recalls and investigations related to vehicle components, including axle hubs. Their website allows users to search for recalls and investigations by specific make, model, and component. You can use their search tool to check if there are any recalls or investigations associated with the axle hub models of interest.

- Owner Forums and Online Communities: Online forums and communities dedicated to specific vehicle makes and models can be a valuable source of information. Owners often share their experiences, including common issues they have encountered with axle hub models. It’s important to consider multiple sources and exercise caution when relying on anecdotal information.

- Service Centers and Mechanics: Local service centers and mechanics who specialize in the specific vehicle make or have experience with the axle hub models in question may be aware of any recalls or common issues. They can provide insights based on their firsthand knowledge and experience.

By consulting these sources, you can gather information about any recalls or common issues associated with specific axle hub models. If any recalls or safety concerns are identified, it is recommended to contact the vehicle manufacturer or a certified dealership to inquire about the necessary actions, such as inspections or repairs, to address the issues.

In summary, recalls and common issues can occur with specific axle hub models. Checking the manufacturer’s website, the NHTSA website, owner forums, and consulting with service centers and mechanics can provide valuable information regarding any recalls or common issues associated with the axle hub models of interest. It’s important to stay informed and take appropriate actions to address any identified safety concerns.

<img src="https://img.hzpt.com/img/axles_shaft_coupling_Spline/spline_shaft_l1.webp" alt="China OEM Truck Parts Brake Hub CZPT 4250 131401020416A005 for Dongfeng/Shacman/Hongyan/Hino/Jmc/Foton/Forland/Isuzu/DFAC/FAW/HOWO/Sinotruk/Sitrak/Shacman/JAC wheel and axle”><img src="https://img.hzpt.com/img/axles_shaft_coupling_Spline/spline_shaft_l2.webp" alt="China OEM Truck Parts Brake Hub CZPT 4250 131401020416A005 for Dongfeng/Shacman/Hongyan/Hino/Jmc/Foton/Forland/Isuzu/DFAC/FAW/HOWO/Sinotruk/Sitrak/Shacman/JAC wheel and axle”>

editor by lmc 2024-10-31

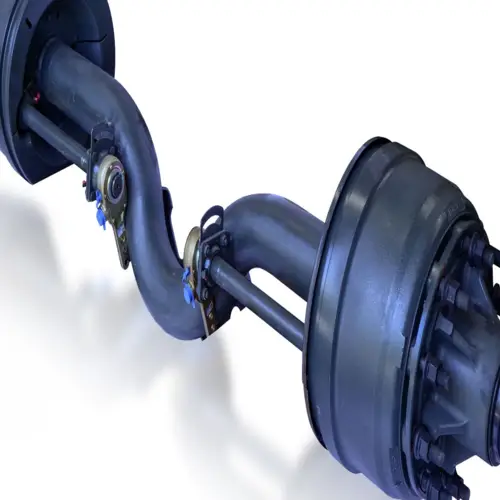

China factory 10t 127mm Round Axle Beam American Loose Type Drop Center Axle with high quality

American Loose Type Drop Center Axle

Our American Loose Type Drop Center Axles are high-quality products manufactured by HangZhou TND Axle Co. Ltd. This product has a 10t capacity and a 127mm round axle beam. It is manufactured in China and is available worldwide.

Product Description

The American Loose Type Drop Center Axle is a reliable and durable product designed for use in trailers, semi-trailers, and other heavy-duty vehicles. It is made of high-quality materials to ensure its longevity.

This axle has a lead time of 25 days for quantities of 1-100 units, 40 days for quantities between 101-300 units, and can be negotiated for quantities over 300 units.

Optional track length, ABS, and automatic slack adjuster are available. Please note that the rights to change the product’s design and specification are reserved.

Technology

Our company has developed the technology of thickening integral shaft by hot extrusion molding with its own intellectual property rights. This self-designed hot-extrusion thickening integrated Axle technology is the first in the world to realize simultaneous thickening and extrusion, and the thickness of the axle end bearing can be customized according to the customer’s special request.

Packaging and Delivery

The goods will be packed according to your requirements and in well protection before delivery, using plastic wrap and wooden pallets.

Frequently Asked Questions

1. What products does your company offer?

A: Our company mainly supplies various industrial products such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, etc.

2. Can you customize the products based on our requirements?

A: Yes, we welcome customization based on drawings and samples provided by our customers.

3. What makes your American Loose Type Drop Center Axle stand out from other similar products?

A: Our American Loose Type Drop Center Axle is made of high-quality materials and is manufactured using our patented hot-extrusion thickening integrated Axle technology. This technology allows us to customize the thickness of the axle end bearing according to the customer’s special request.

4. How long is the delivery time?

A: For quantities of 1-100 units, the lead time is 25 days. For quantities between 101-300 units, the lead time is 40 days. Quantities over 300 units can be negotiated.

5. What is your pricing policy?

A: We will quote you the best price possible based on your requirements. Please let us know the quantity and material of the product you need. The more quantity ordered, the better the price offered.

Performance Characteristics of Axle

Axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. Axles should be able to bear the weight of the vehicle or machinery and maintain stability during operation. Durability is essential as axles are subjected to constant stress and pressure, and wear resistance is necessary to prevent damage and prolong the lifespan of axles.

Types and Characteristics of Axle

There are several types of axles, including straight, drop, and stub axles. Straight axles are the simplest type, consisting of a single shaft connecting the wheels. Drop axles are designed for larger vehicles and feature a drop in the center to lower the ride height. Stub axles are used in trailers and have a pivot point that allows the wheels to turn. The characteristics of axles vary depending on the type and application, but they all share the ability to support and rotate wheels.

Advantages of Axle Made of Different Materials

Axles can be made of various materials, including steel, aluminum, and titanium. Steel axles are durable and strong, making them ideal for heavy-duty applications. Aluminum axles are lightweight and corrosion-resistant, making them suitable for high-performance applications. Titanium axles are strong, lightweight, and corrosion-resistant, making them ideal for racing and other high-performance applications. The choice of material depends on the intended application and performance requirements.

Application of Axle in Various Fields

Axles are essential components in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. In the automotive industry, axles are used in cars, trucks, and other vehicles to support and rotate the wheels. Heavy machinery such as excavators, bulldozers, and cranes also use axles to provide support and movement. Trailers and railway systems require axles to support and move cargo and passengers. Bicycles use axles to support and rotate the wheels, providing the rider with propulsion and stability.

Future Development Trends and Opportunities of Axle Products

The future development of axle products is focused on improving performance and reducing weight. Lightweight materials such as carbon fiber and composites are being used to reduce the weight of axles while maintaining strength and durability. Advancements in technology, such as 3D printing, are also being used to create complex geometries and designs that improve performance and reduce weight. The increasing demand for electric and autonomous vehicles is also creating opportunities for new axle designs and applications.

Choosing a Suitable Axle

The choice of a suitable axle depends on several factors, including load capacity, material, type of axle, dimensions and specifications, braking system compatibility, and application type. The load capacity should be sufficient to support the weight of the vehicle or machinery. The material should be chosen based on the intended application and performance requirements. The type of axle should be selected based on the vehicle or machinery design. The dimensions and specifications should be compatible with the vehicle or machinery. The braking system compatibility should be considered to ensure proper operation. The application type should be evaluated to determine the appropriate axle design and performance characteristics.

Conclusion

In conclusion, axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. The choice of material depends on the intended application and performance requirements. Axles are used in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. The future development of axle products is focused on improving performance and reducing weight, creating opportunities for new designs and applications.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

China best German Type 16t Assemble Truck Rear Steer Axles for Trailer 25 Ton American Type Axle Rear Steer Axle air compressor for car

German Type 16t Assemble Truck Rear Steer Axles for Trailer

The German Type 16t Assemble Truck Rear Steer Axles for Trailer are high-quality trailer axles that are designed to provide superior performance in a variety of applications. These axles are made from top-quality materials and are built to last, ensuring that your trailer will provide reliable service for years to come.

Product Description

The China best American Type Axle Rear Steer Axle air compressor for car and Manufacturer 8t-25t American Inboard Built-in Brake Drum Axle for Trailer truck is a highly versatile and reliable piece of equipment that is ideal for a wide range of applications. It features a range of advanced design features and technologies that make it one of the most advanced trailer axles on the market today.

Features and Benefits

- High-quality construction materials

- Advanced design features and technologies

- Superior performance and reliability

- Designed to provide long-lasting service life

- Easy to install and maintain

Specifications

The China best American Type Axle Rear Steer Axle air compressor for car and Manufacturer 8t-25t American Inboard Built-in Brake Drum Axle for Trailer truck is available in a range of different specifications to suit the needs of a variety of different applications. Some of the key specifications of this product include:

| Axle Type | Max Capacity(t) | Track(mm) | Brake(mm) | Spring Seat Installation | Axle Beam(mm) | Centre Distance Of Brake Chamber(mm) | Wheel Fixing | Total Length(mm) | Recommended Wheel | Axle Wright(kg) | ||

| Stud | P.C.D(mm) | H(mm) | ||||||||||

| JS08Y2C15 | 8 | 1850 | 420*150 | >=1080 | 127 | 428 | 10*M22*1.5 ISO | 335 | 280.8 | ~2145 | 7.5V-20 | 323 |

| JS13Y9C10 | 13 | 1840 | 420*180 | >=970 | 127 | 380 | 10*M22*1.5 ISO | 335 | 280.8 | ~2180 | 7.5V-20 | 342 |

| JS13F1B10 | 13 | 1840 | 420*180 | >=930 | 150 | 380 | 10*M22*1.5 ISO | 335 | 280.8 | ~2180 | 7.5V-20 | 340 |

| JS14F1B11 | 14 | 1840 | 420*220 | >=930 | 150 | 340 | 10*M22*1.5 ISO | 335 | 280.8 | ~2180 | 7.5V-20 | 358 |

| JS15F6B11 | 15 | 1850 | 420*180 | >=940 | 150 | 390 | 10*M22*1.5 ISO | 335 | 280.8 | ~2200 | 8.0V-20 | 370 |

| JS16F6B11 | 16 | 1850 | 420*220 | >=940 | 150 | 350 | 10*M22*1.5 ISO | 335 | 280.8 | ~2200 | 8.0V-20 | 388 |

| JS20F8B12 | 20 | 1850 | 420*220 | >=940 | 150 | 345 | 10*M24*1.5 ISO | 335 | 280.8 | ~2247 | 8.0V-20 | 430 |

| JS25H8B12 | 25 | 1850 | 420*220 | >=940 | 150 | 340 | 10*M24*1.5 ISO | 335 | 280.8 | ~2215 | 8.0V-20 | 474 |

Detailed Photos

Packaging & Shipping

We offer a range of packaging and shipping options to suit the needs of our customers. Our products are carefully packaged to ensure that they are delivered to our customers in perfect condition, and we work closely with our shipping partners to ensure that our products are delivered on time and at a competitive price.

Frequently Asked Questions (FAQs)

1. What is the load capacity of the China best American Type Axle Rear Steer Axle?

The load capacity of the China best American Type Axle Rear Steer Axle varies depending on the specific model. Please refer to the specifications table for more information.

2. Is the China best American Type Axle Rear Steer Axle easy to install?

Yes, the China best American Type Axle Rear Steer Axle is designed to be easy to install and maintain. However, we recommend that installation be carried out by a professional mechanic to ensure that the axle is installed correctly and safely.

3. What kind of materials are used to make the China best American Type Axle Rear Steer Axle?

The China best American Type Axle Rear Steer Axle is made from high-quality materials that are designed to provide superior strength, durability, and performance. These materials include top-quality steel, aluminum, and other alloys.

4. What kind of maintenance does the China best American Type Axle Rear Steer Axle require?

The China best American Type Axle Rear Steer Axle is designed to be low-maintenance, but regular inspections and maintenance are recommended to ensure that the axle is functioning properly and to prevent damage or wear.

5. Can the China best American Type Axle Rear Steer Axle be customized to suit specific requirements?

Yes, the China best American Type Axle Rear Steer Axle can be customized to suit the specific needs of our customers. Please contact us to discuss your requirements and to receive a quote.

Our company offers a wide range of other high-quality industrial products, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing our customers with the highest-quality products, the best prices, and the most thoughtful service possible. Customers are welcome to customize their products with drawings and samples.

Performance Characteristics of Axle

Axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. Axles should be able to bear the weight of the vehicle or machinery and maintain stability during operation. Durability is essential as axles are subjected to constant stress and pressure, and wear resistance is necessary to prevent damage and prolong the lifespan of axles.

Types and Characteristics of Axle

There are several types of axles, including straight, drop, and stub axles. Straight axles are the simplest type, consisting of a single shaft connecting the wheels. Drop axles are designed for larger vehicles and feature a drop in the center to lower the ride height. Stub axles are used in trailers and have a pivot point that allows the wheels to turn. The characteristics of axles vary depending on the type and application, but they all share the ability to support and rotate wheels.

Advantages of Axle Made of Different Materials

Axles can be made of various materials, including steel, aluminum, and titanium. Steel axles are durable and strong, making them ideal for heavy-duty applications. Aluminum axles are lightweight and corrosion-resistant, making them suitable for high-performance applications. Titanium axles are strong, lightweight, and corrosion-resistant, making them ideal for racing and other high-performance applications. The choice of material depends on the intended application and performance requirements.

Application of Axle in Various Fields

Axles are essential components in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. In the automotive industry, axles are used in cars, trucks, and other vehicles to support and rotate the wheels. Heavy machinery such as excavators, bulldozers, and cranes also use axles to provide support and movement. Trailers and railway systems require axles to support and move cargo and passengers. Bicycles use axles to support and rotate the wheels, providing the rider with propulsion and stability.

Future Development Trends and Opportunities of Axle Products

The future development of axle products is focused on improving performance and reducing weight. Lightweight materials such as carbon fiber and composites are being used to reduce the weight of axles while maintaining strength and durability. Advancements in technology, such as 3D printing, are also being used to create complex geometries and designs that improve performance and reduce weight. The increasing demand for electric and autonomous vehicles is also creating opportunities for new axle designs and applications.

Choosing a Suitable Axle

The choice of a suitable axle depends on several factors, including load capacity, material, type of axle, dimensions and specifications, braking system compatibility, and application type. The load capacity should be sufficient to support the weight of the vehicle or machinery. The material should be chosen based on the intended application and performance requirements. The type of axle should be selected based on the vehicle or machinery design. The dimensions and specifications should be compatible with the vehicle or machinery. The braking system compatibility should be considered to ensure proper operation. The application type should be evaluated to determine the appropriate axle design and performance characteristics.

Conclusion

In conclusion, axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. The choice of material depends on the intended application and performance requirements. Axles are used in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. The future development of axle products is focused on improving performance and reducing weight, creating opportunities for new designs and applications.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

China Custom 2200lbs Capacity 5bolt Trailer Parts Rubber Unbraked Half Torsion Beam Spindle Stub Axles with Idler Wheel air compressor portable

China Custom 2200lbs Capacity 5bolt Trailer Parts Rubber Unbraked Half Torsion Beam Spindle Stub Axles with Idler Wheel

Product Description

If you’re in need of high-quality trailer parts, look no further than our China Custom 2200lbs Capacity 5bolt Trailer Parts Rubber Unbraked Half Torsion Beam Spindle Stub Axles with Idler Wheel. These axles offer a wide range of load capacity options to meet your specific requirements. With their strong and durable spindle, they are built to last and are easy to replace if needed. Not only do these axles provide a smooth and quiet ride, but they can also eliminate the need for a separate trailer axle.

| Part Number | Hub Type | Cap. Per Pair | P.C.D. | HUB Face (TR) | Axle Length | Start Angle | Finish |

| TA1100HN | Idler Hub | 1100 lbs | 4-4.0″, 5-4.5″ | Flexible | 600mm | various | Black/Galv. |

| TA1750HN | Idler Hub | 1750 lbs | 4-4.0″, 5-4.5″ | Flexible | 600mm | various | Black/Galv. |

| TA2200HN | Idler Hub | 2200 lbs | 4-4.0″, 5-4.5″ | Flexible | 650mm | various | Black/Galv. |

| TA2200HE | 9″ Electric Brake Hub | 2200 lbs | 4-4.0″, 5-4.5″ | Flexible | 650mm | various | Black/Galv. |

| TA2200HH | 9″ Hydraulic Brake Hub | 2200 lbs | 4-4.0″, 5-4.5″ | Flexible | 650mm | various | Black/Galv. |

| TA3500HE | 10″ Electric Brake Hub | 3500 lbs | 5-4.5″, 6-5.5″ | Flexible | 800mm | various | Black/Galv. |

| TA3500HH | 10″ Hydraulic Brake Hub | 3500 lbs | 5-4.5″, 6-5.5″ | Flexible | 800mm | various | Black/Galv. |

Frequently Asked Questions

1) Do you have a factory?

Yes, we have our own factory equipped with experienced engineers who can meet your unique requirements.

2) Do you provide samples? Is there a cost?

Yes, we can provide samples for you to check and approve. Please note that there may be a cost for normal samples, but it can be considered for return once an order is placed.

3) What is your MOQ?

For trailer axles, our MOQ is 100 units. For trailer axle parts assembly, the MOQ is 3000 units.

4) Can you manufacture parts according to our specific size?

Yes, we can support your request for specific sizes by making tooling adjustments.

5) What are your payment terms?

For bulk orders, we generally accept TT (telegraphic transfer) payment. Irrevocable L/C (letter of credit) at sight is also workable. For samples, we accept payment via Paypal.

If you have any other questions or inquiries, please feel free to contact us. We are here to provide you with high-quality products, competitive prices, and excellent customer service.

Our company also specializes in various other industrial products, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, and bushings. We welcome customizations based on your drawings and samples.

Other Products and Businesses

In addition to our trailer parts, we offer a wide range of other products and services. Whether you need agricultural gearboxes, power output shafts, or hydraulic couplings, we have you covered. Our products are of the highest quality, competitively priced, and backed by our commitment to exceptional customer service. Feel free to explore our website or contact us for more information.

Performance Characteristics of Axle

Axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. Axles should be able to bear the weight of the vehicle or machinery and maintain stability during operation. Durability is essential as axles are subjected to constant stress and pressure, and wear resistance is necessary to prevent damage and prolong the lifespan of axles.

Types and Characteristics of Axle

There are several types of axles, including straight, drop, and stub axles. Straight axles are the simplest type, consisting of a single shaft connecting the wheels. Drop axles are designed for larger vehicles and feature a drop in the center to lower the ride height. Stub axles are used in trailers and have a pivot point that allows the wheels to turn. The characteristics of axles vary depending on the type and application, but they all share the ability to support and rotate wheels.

Advantages of Axle Made of Different Materials

Axles can be made of various materials, including steel, aluminum, and titanium. Steel axles are durable and strong, making them ideal for heavy-duty applications. Aluminum axles are lightweight and corrosion-resistant, making them suitable for high-performance applications. Titanium axles are strong, lightweight, and corrosion-resistant, making them ideal for racing and other high-performance applications. The choice of material depends on the intended application and performance requirements.

Application of Axle in Various Fields

Axles are essential components in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. In the automotive industry, axles are used in cars, trucks, and other vehicles to support and rotate the wheels. Heavy machinery such as excavators, bulldozers, and cranes also use axles to provide support and movement. Trailers and railway systems require axles to support and move cargo and passengers. Bicycles use axles to support and rotate the wheels, providing the rider with propulsion and stability.

Future Development Trends and Opportunities of Axle Products

The future development of axle products is focused on improving performance and reducing weight. Lightweight materials such as carbon fiber and composites are being used to reduce the weight of axles while maintaining strength and durability. Advancements in technology, such as 3D printing, are also being used to create complex geometries and designs that improve performance and reduce weight. The increasing demand for electric and autonomous vehicles is also creating opportunities for new axle designs and applications.

Choosing a Suitable Axle

The choice of a suitable axle depends on several factors, including load capacity, material, type of axle, dimensions and specifications, braking system compatibility, and application type. The load capacity should be sufficient to support the weight of the vehicle or machinery. The material should be chosen based on the intended application and performance requirements. The type of axle should be selected based on the vehicle or machinery design. The dimensions and specifications should be compatible with the vehicle or machinery. The braking system compatibility should be considered to ensure proper operation. The application type should be evaluated to determine the appropriate axle design and performance characteristics.

Conclusion

In conclusion, axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. The choice of material depends on the intended application and performance requirements. Axles are used in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. The future development of axle products is focused on improving performance and reducing weight, creating opportunities for new designs and applications.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

China wholesaler High-Quality Wheel Side Front Axle for Lada Vaz Models 21214-2201012 Cardan manufacturer

High-Quality Wheel Side Front Axle for Lada Vaz Models 21214-2201012

Product Description

The wheel side front axle is a high-quality component designed specifically for Lada Vaz models 21214-2201012. It is manufactured by a reliable and experienced wholesaler in China.

Model 2 Drive Shaft Introduction

The drive shaft is an essential part of the automotive transmission system. It is responsible for transferring engine power to the wheels, ensuring smooth vehicle operation and excellent handling performance.

Product Overview

The 2 drive shaft is constructed using high-strength alloy steel, providing exceptional wear resistance and fatigue strength. It undergoes precision machining to ensure dimensional accuracy and surface smoothness, resulting in enhanced durability. The lightweight design contributes to improved fuel efficiency and handling. Additionally, the drive shaft is treated to resist corrosion, making it suitable for various challenging environments.

Applications

This drive shaft is widely used in sedans, SUVs, and commercial vehicles. It is compatible with front-wheel drive, rear-wheel drive, and four-wheel drive systems, satisfying diverse powertrain needs.

Installation and Maintenance

- Installation: It is important to follow the vehicle manufacturer’s installation manual for proper alignment and secure fastening of the drive shaft.

- Maintenance: Regularly check the drive shaft’s working condition for excessive wear and corrosion. Ensure proper lubrication to extend its lifespan.

Summary

The 2 drive shaft is an indispensable component of modern automotive transmission systems. Its exceptional performance and reliability provide robust power support and driving stability to your vehicle.

| PRODUCTS NAME | Drive Shaft |

| VEHICLE FITMENT | UAZ |

| LENGTH | 8 |

| Warranty | 1 Year |

| Condition: | NEW |

| Color: | BLACK/STEEL |

| Certification: | ISO, TS16949 |

| Type: | Drive Shaft |

This is just one of the high-quality products we offer. Our company specializes in supplying various industrial products ranging from agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, to bushings. We take pride in offering excellent products at preferential prices, along with thoughtful services. Customers are welcome to customize products based on their drawings and samples.

Frequently Asked Questions

- What are the main features of the 2 drive shaft?

- Which vehicle models are compatible with this drive shaft?

- How should I install the drive shaft?

- What maintenance should I perform on the drive shaft?

- Can I customize the drive shaft to fit my specific requirements?

Performance Characteristics of Axle

Axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. Axles should be able to bear the weight of the vehicle or machinery and maintain stability during operation. Durability is essential as axles are subjected to constant stress and pressure, and wear resistance is necessary to prevent damage and prolong the lifespan of axles.

Types and Characteristics of Axle

There are several types of axles, including straight, drop, and stub axles. Straight axles are the simplest type, consisting of a single shaft connecting the wheels. Drop axles are designed for larger vehicles and feature a drop in the center to lower the ride height. Stub axles are used in trailers and have a pivot point that allows the wheels to turn. The characteristics of axles vary depending on the type and application, but they all share the ability to support and rotate wheels.

Advantages of Axle Made of Different Materials

Axles can be made of various materials, including steel, aluminum, and titanium. Steel axles are durable and strong, making them ideal for heavy-duty applications. Aluminum axles are lightweight and corrosion-resistant, making them suitable for high-performance applications. Titanium axles are strong, lightweight, and corrosion-resistant, making them ideal for racing and other high-performance applications. The choice of material depends on the intended application and performance requirements.

Application of Axle in Various Fields

Axles are essential components in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. In the automotive industry, axles are used in cars, trucks, and other vehicles to support and rotate the wheels. Heavy machinery such as excavators, bulldozers, and cranes also use axles to provide support and movement. Trailers and railway systems require axles to support and move cargo and passengers. Bicycles use axles to support and rotate the wheels, providing the rider with propulsion and stability.

Future Development Trends and Opportunities of Axle Products

The future development of axle products is focused on improving performance and reducing weight. Lightweight materials such as carbon fiber and composites are being used to reduce the weight of axles while maintaining strength and durability. Advancements in technology, such as 3D printing, are also being used to create complex geometries and designs that improve performance and reduce weight. The increasing demand for electric and autonomous vehicles is also creating opportunities for new axle designs and applications.

Choosing a Suitable Axle

The choice of a suitable axle depends on several factors, including load capacity, material, type of axle, dimensions and specifications, braking system compatibility, and application type. The load capacity should be sufficient to support the weight of the vehicle or machinery. The material should be chosen based on the intended application and performance requirements. The type of axle should be selected based on the vehicle or machinery design. The dimensions and specifications should be compatible with the vehicle or machinery. The braking system compatibility should be considered to ensure proper operation. The application type should be evaluated to determine the appropriate axle design and performance characteristics.

Conclusion

In conclusion, axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. The choice of material depends on the intended application and performance requirements. Axles are used in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. The future development of axle products is focused on improving performance and reducing weight, creating opportunities for new designs and applications.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

China Custom 12t 14t 16t 18t BPW Germany Type Trailer Truck Axle for Semi Trailer Vehicle Part air compressor for car

China Custom 12t 14t 16t 18t BPW Germany Type Trailer Truck Axle for Semi Trailer Vehicle Part air compressor for car

Product Description

Introducing our China Custom Trailer Truck Axle, designed for semi trailer vehicles. This axle is manufactured with precision and adheres to high-quality standards. It is compatible with various trailer types and provides reliable performance on the road.

Key Features:

- Capacity: 12t, 14t, 16t, 18t

- Axle Type: BPW Germany Type

- High-quality construction and materials

- Customizable according to specific requirements

- Designed for optimal performance and durability

Product Specifications

Our China Custom Trailer Truck Axle comes in different capacities and dimensions. Here are the specifications for our 16t Axle:

| Part No. | Max. Capacity | Distance of Chamber | Track | Axle Beam | Brake Size | Length | Bearing | Weight |

|---|---|---|---|---|---|---|---|---|

| XDE16-2001 | 16000 | 356 | 1850 | 150 | 420×200 | 2242 | 32314/32222 | 468 |

Our 16t Axle is designed with a maximum capacity of 16000 and features a durable axle beam, suitable for heavy loads. Its track width and axle beam dimensions ensure stability and performance on the road. With high-quality bearings and precise construction, this axle provides reliable and safe operation.

Product Images

FAQs

1. What are the different capacities available for the China Custom Trailer Truck Axle?

The China Custom Trailer Truck Axle is available in capacities ranging from 12t to 18t. This allows you to choose the axle that best suits your specific requirements.

2. Can the China Custom Trailer Truck Axle be customized?

Yes, the China Custom Trailer Truck Axle can be customized according to your specific needs. Our team can work with you to create an axle that meets your unique requirements.

3. Is the China Custom Trailer Truck Axle compatible with all types of semi trailers?

Yes, the China Custom Trailer Truck Axle is designed to be compatible with various types of semi trailers. Whether you have a flatbed trailer, a container trailer, or any other type, this axle can provide reliable performance.

4. Are the bearings of the China Custom Trailer Truck Axle of high quality?

Yes, the China Custom Trailer Truck Axle is equipped with high-quality bearings. These bearings are known for their durability, high rotating speed, and resistance to abrasion and heat, ensuring reliable and smooth operation.

5. What are the advantages of the China Custom Trailer Truck Axle?

The China Custom Trailer Truck Axle offers several advantages, including a high load capacity, precise construction, and reliability on the road. It is designed to withstand heavy loads and provide long-lasting performance, making it an excellent choice for your trailer.

Other Products and Services

In addition to our China Custom Trailer Truck Axle, we also offer a wide range of other industrial products. Our product lineup includes agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in providing high-quality products at competitive prices, backed by exceptional customer service.

With our expertise and advanced manufacturing capabilities, we can accommodate custom orders based on your drawings and samples. We strive to meet our customers’ specific requirements and ensure their satisfaction.

Performance Characteristics of Axle

Axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. Axles should be able to bear the weight of the vehicle or machinery and maintain stability during operation. Durability is essential as axles are subjected to constant stress and pressure, and wear resistance is necessary to prevent damage and prolong the lifespan of axles.

Types and Characteristics of Axle

There are several types of axles, including straight, drop, and stub axles. Straight axles are the simplest type, consisting of a single shaft connecting the wheels. Drop axles are designed for larger vehicles and feature a drop in the center to lower the ride height. Stub axles are used in trailers and have a pivot point that allows the wheels to turn. The characteristics of axles vary depending on the type and application, but they all share the ability to support and rotate wheels.

Advantages of Axle Made of Different Materials

Axles can be made of various materials, including steel, aluminum, and titanium. Steel axles are durable and strong, making them ideal for heavy-duty applications. Aluminum axles are lightweight and corrosion-resistant, making them suitable for high-performance applications. Titanium axles are strong, lightweight, and corrosion-resistant, making them ideal for racing and other high-performance applications. The choice of material depends on the intended application and performance requirements.

Application of Axle in Various Fields

Axles are essential components in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. In the automotive industry, axles are used in cars, trucks, and other vehicles to support and rotate the wheels. Heavy machinery such as excavators, bulldozers, and cranes also use axles to provide support and movement. Trailers and railway systems require axles to support and move cargo and passengers. Bicycles use axles to support and rotate the wheels, providing the rider with propulsion and stability.

Future Development Trends and Opportunities of Axle Products

The future development of axle products is focused on improving performance and reducing weight. Lightweight materials such as carbon fiber and composites are being used to reduce the weight of axles while maintaining strength and durability. Advancements in technology, such as 3D printing, are also being used to create complex geometries and designs that improve performance and reduce weight. The increasing demand for electric and autonomous vehicles is also creating opportunities for new axle designs and applications.

Choosing a Suitable Axle

The choice of a suitable axle depends on several factors, including load capacity, material, type of axle, dimensions and specifications, braking system compatibility, and application type. The load capacity should be sufficient to support the weight of the vehicle or machinery. The material should be chosen based on the intended application and performance requirements. The type of axle should be selected based on the vehicle or machinery design. The dimensions and specifications should be compatible with the vehicle or machinery. The braking system compatibility should be considered to ensure proper operation. The application type should be evaluated to determine the appropriate axle design and performance characteristics.

Conclusion

In conclusion, axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. The choice of material depends on the intended application and performance requirements. Axles are used in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. The future development of axle products is focused on improving performance and reducing weight, creating opportunities for new designs and applications.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

China Professional 13 T 15t 16t 20t Trailer Axle for Heavy Duty Truck air compressor portable

Heavy Duty Trailer Axles for Trucks

Product Overview

Our heavy-duty trailer axles are the perfect solution for your trucking needs. With a maximum capacity of 10T~20T, these axles can handle any load you throw at them. Our axles are available in 1820MM/1850MM track sizes, or we can customize them to fit your specific requirements. The P.C.D is Φ285.75/Φ335, and the hole diameter is 281MM. The distance of brake chamber ranges from 354~510, and the weight of the axles ranges from 330~425KGS. The axle tube shape can be either square or round.

Customizable Options

Our axles can be customized according to your specific needs. From the track size to the weight capacity and the axle tube shape, we can tailor our products to your requirements. We also offer the option of installing an ABS explosion protection system for added safety.

Why Choose Our Trailer Axles?

Our trailer axles are built to last. We use only high-quality materials in our production process, ensuring that our products are durable and reliable. Our axles are also easy to install and maintain, making them the perfect choice for any trucking operation.

High-Quality Products

We take pride in the quality of our products. All of our trailer axles are thoroughly tested to ensure they meet our high standards. We use only the best materials in our production process, ensuring that our products are built to last.

Competitive Prices

We offer our products at competitive prices, without compromising on quality. We believe that everyone should have access to high-quality trailer axles, which is why we offer our products at affordable prices.

Excellent Customer Service

We are committed to providing our customers with the best possible service. Our team is always ready to assist you with any questions or concerns you may have. We also offer customization options, allowing you to tailor our products to your specific needs.

Customization

Customers are welcome to customize our trailer axles according to their drawings and samples. We offer a wide range of customization options, from the track size to the weight capacity and the axle tube shape.

Our company offers a wide range of industrial products, such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are dedicated to providing our customers with high-quality products, competitive prices, and excellent customer service. Contact us today to learn more about our products and services.

Frequently Asked Questions

1. What is the weight capacity of your trailer axles?

Our trailer axles have a maximum capacity of 10T~20T, or we can customize them to fit your specific requirements.

2. What track sizes are available for your trailer axles?

Our trailer axles are available in 1820MM/1850MM track sizes, or we can customize them to fit your specific requirements.

3. Can I customize the axle tube shape?

Yes, we offer the option of customizing the axle tube shape to your specific requirements.

4. Do your trailer axles come with an ABS explosion protection system?

We offer the option of installing an ABS explosion protection system for added safety.

5. Do you offer customization options?

Yes, customers are welcome to customize our trailer axles according to their drawings and samples. We offer a wide range of customization options.

Performance Characteristics of Axle

Axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. Axles should be able to bear the weight of the vehicle or machinery and maintain stability during operation. Durability is essential as axles are subjected to constant stress and pressure, and wear resistance is necessary to prevent damage and prolong the lifespan of axles.

Types and Characteristics of Axle

There are several types of axles, including straight, drop, and stub axles. Straight axles are the simplest type, consisting of a single shaft connecting the wheels. Drop axles are designed for larger vehicles and feature a drop in the center to lower the ride height. Stub axles are used in trailers and have a pivot point that allows the wheels to turn. The characteristics of axles vary depending on the type and application, but they all share the ability to support and rotate wheels.

Advantages of Axle Made of Different Materials

Axles can be made of various materials, including steel, aluminum, and titanium. Steel axles are durable and strong, making them ideal for heavy-duty applications. Aluminum axles are lightweight and corrosion-resistant, making them suitable for high-performance applications. Titanium axles are strong, lightweight, and corrosion-resistant, making them ideal for racing and other high-performance applications. The choice of material depends on the intended application and performance requirements.

Application of Axle in Various Fields

Axles are essential components in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. In the automotive industry, axles are used in cars, trucks, and other vehicles to support and rotate the wheels. Heavy machinery such as excavators, bulldozers, and cranes also use axles to provide support and movement. Trailers and railway systems require axles to support and move cargo and passengers. Bicycles use axles to support and rotate the wheels, providing the rider with propulsion and stability.

Future Development Trends and Opportunities of Axle Products

The future development of axle products is focused on improving performance and reducing weight. Lightweight materials such as carbon fiber and composites are being used to reduce the weight of axles while maintaining strength and durability. Advancements in technology, such as 3D printing, are also being used to create complex geometries and designs that improve performance and reduce weight. The increasing demand for electric and autonomous vehicles is also creating opportunities for new axle designs and applications.

Choosing a Suitable Axle

The choice of a suitable axle depends on several factors, including load capacity, material, type of axle, dimensions and specifications, braking system compatibility, and application type. The load capacity should be sufficient to support the weight of the vehicle or machinery. The material should be chosen based on the intended application and performance requirements. The type of axle should be selected based on the vehicle or machinery design. The dimensions and specifications should be compatible with the vehicle or machinery. The braking system compatibility should be considered to ensure proper operation. The application type should be evaluated to determine the appropriate axle design and performance characteristics.

Conclusion

In conclusion, axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. The choice of material depends on the intended application and performance requirements. Axles are used in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. The future development of axle products is focused on improving performance and reducing weight, creating opportunities for new designs and applications.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

China high quality 1 Ton Electric Vehicle Transaxle Drive System 1300W Motor Rear Axle 1: 33 Differential Low Speed Engineering Electric Tricycle Drive Axle Assembly air compressor repair near me

China High Quality 1 Ton Electric Vehicle Transaxle Drive System

The China High Quality 1 Ton Electric Vehicle Transaxle Drive System is a reliable and efficient solution for electric tricycle drive axle assembly. With its powerful 1300W motor and 1:33 differential ratio, it provides low-speed engineering capabilities for various transportation needs. This drive system is designed to handle a total weight of 1000kg (car weight + goods weight), making it ideal for heavy-duty applications.

Product Description

The 1300W 1:33 Low Speed Rear Axle Kit is a high-performance rear axle assembly that is specifically designed for electric tricycles. It features a durable construction and a precise 1:33 differential ratio, providing optimal power transmission and smooth operation. The kit is capable of handling a total weight of 1000kg, ensuring reliable performance even under heavy load.

Detailed Photos

Packaging & Shipping

Our products are carefully packaged to ensure safe transportation. Small products are generally packaged in cartons, while large products or bulk goods are packed in wooden cases for added protection.

Our Advantages

- High-quality products

- Competitive prices

- Customization options available

- Fast and reliable shipping

- Excellent after-sales service

After Sales Service

1. The motor and controller of the whole vehicle and the whole vehicle modification kit are covered by a 1-year warranty.

2. Other wearing parts have a 3-month warranty period. If any damage is reported within 15 days after receiving the goods, we will provide free replacement or reissue.

3. Please note that tires, shock absorbers, rear axles, and other parts not meeting the product specifications or damaged due to overload or human causes are not covered by the warranty.

4. If a problem occurs during the product quality assurance period, the goods need to be returned for replacement or quality assurance services. If the goods are not returned and need to be sold after-sales, we offer two solutions:

– Method 1: We recommend placing the next batch of orders and replacing the new goods together with the newly purchased goods. The freight will be borne by the buyer.

– Method 2: The customer can choose to repurchase the product at a 50% discount of the original price, with the freight borne by the buyer.

FAQ

Q: Are you a trading company or a factory?

A: We are a manufacturer with our own production base. You are warmly welcomed to visit us.

Q: What kind of product quality does your factory offer?

A: We provide the most competitive products at the highest quality price.

Q: What’s your best price for this product?

A: We will quote you the best price based on your quantity. Please let us know the quantity you want when making an inquiry.

Q: Can you print our logos on the parts?

A: Yes, we can provide laser printing logos and engrave logos according to your requirements.

Q: How does your factory ensure quality control?

A: We use environmentally-friendly raw materials and have skillful workers who pay attention to every detail in the production and packing process. Our quality control department is responsible for ensuring quality in each process.

For more information about our products, please visit: productmanage.do?xcase=view&prodId=oGFrcTKPCpkB

Other Products and Services

Our company specializes in supplying various industrial products, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We pride ourselves on offering high-quality products, competitive prices, and thoughtful services. Customers are welcome to customize products based on their drawings and samples.

Performance Characteristics of Axle

Axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. Axles should be able to bear the weight of the vehicle or machinery and maintain stability during operation. Durability is essential as axles are subjected to constant stress and pressure, and wear resistance is necessary to prevent damage and prolong the lifespan of axles.

Types and Characteristics of Axle

There are several types of axles, including straight, drop, and stub axles. Straight axles are the simplest type, consisting of a single shaft connecting the wheels. Drop axles are designed for larger vehicles and feature a drop in the center to lower the ride height. Stub axles are used in trailers and have a pivot point that allows the wheels to turn. The characteristics of axles vary depending on the type and application, but they all share the ability to support and rotate wheels.

Advantages of Axle Made of Different Materials

Axles can be made of various materials, including steel, aluminum, and titanium. Steel axles are durable and strong, making them ideal for heavy-duty applications. Aluminum axles are lightweight and corrosion-resistant, making them suitable for high-performance applications. Titanium axles are strong, lightweight, and corrosion-resistant, making them ideal for racing and other high-performance applications. The choice of material depends on the intended application and performance requirements.

Application of Axle in Various Fields

Axles are essential components in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. In the automotive industry, axles are used in cars, trucks, and other vehicles to support and rotate the wheels. Heavy machinery such as excavators, bulldozers, and cranes also use axles to provide support and movement. Trailers and railway systems require axles to support and move cargo and passengers. Bicycles use axles to support and rotate the wheels, providing the rider with propulsion and stability.

Future Development Trends and Opportunities of Axle Products

The future development of axle products is focused on improving performance and reducing weight. Lightweight materials such as carbon fiber and composites are being used to reduce the weight of axles while maintaining strength and durability. Advancements in technology, such as 3D printing, are also being used to create complex geometries and designs that improve performance and reduce weight. The increasing demand for electric and autonomous vehicles is also creating opportunities for new axle designs and applications.

Choosing a Suitable Axle

The choice of a suitable axle depends on several factors, including load capacity, material, type of axle, dimensions and specifications, braking system compatibility, and application type. The load capacity should be sufficient to support the weight of the vehicle or machinery. The material should be chosen based on the intended application and performance requirements. The type of axle should be selected based on the vehicle or machinery design. The dimensions and specifications should be compatible with the vehicle or machinery. The braking system compatibility should be considered to ensure proper operation. The application type should be evaluated to determine the appropriate axle design and performance characteristics.

Conclusion

In conclusion, axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. The choice of material depends on the intended application and performance requirements. Axles are used in various fields, including the automotive industry, heavy machinery, trailers, railway systems, bicycles, and more. The future development of axle products is focused on improving performance and reducing weight, creating opportunities for new designs and applications.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

China manufacturer Hydraulic Brake BPW Trailer Axle Trailer Part Truck Axle Parts Trailer Axle BPW Axle for Sale with Great quality

High-Quality Hydraulic Brake BPW Trailer Axle for Sale

Our hydraulic brake BPW trailer axle is a high-quality and reliable product that is perfect for use in a variety of industrial settings. With a max capacity ranging from 8t-25t, this trailer axle is ideal for use in heavy-duty trucks and trailers.

Product Description

This American inboard built-in brake drum axle is designed to meet the highest technical standards and provide optimal performance in even the most demanding conditions. With precision engineering and advanced manufacturing technologies, our trailer axles are built to last and deliver exceptional results.

Our trailer axles come in a variety of sizes and capacities, ranging from 8t-25t. They are designed with safety and performance in mind, with features like track width, brake size, and spring seat installation all optimized for maximum performance and stability.

Technical Specifications

| Axle Type | Max Capacity (t) | Track (mm) | Brake (mm) | Spring Seat Installation | Axle Beam (mm) | Center Distance Of Brake Chamber (mm) | Wheel Fixing | Total Length (mm) | Recommended Wheel | Axle Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|

| JS08Y2C15 | 8 | 1850 | 420*150 | >=1080 | 127 | 428 | 10*M22*1.5 ISO | 335 | 280.8 | 323 |

| JS13Y9C10 | 13 | 1840 | 420*180 | >=970 | 127 | 380 | 10*M22*1.5 ISO | 335 | 280.8 | 342 |

| JS13F1B10 | 13 | 1840 | 420*180 | >=930 | 150 | 380 | 10*M22*1.5 ISO | 335 | 280.8 | 340 |

| JS14F1B11 | 14 | 1840 | 420*220 | >=930 | 150 | 340 | 10*M22*1.5 ISO | 335 | 280.8 | 358 |

| JS15F6B11 | 15 | 1850 | 420*180 | >=940 | 150 | 390 | 10*M22*1.5 ISO | 335 | 280.8 | 370 |

| JS16F6B11 | 16 | 1850 | 420*220 | >=940 | 150 | 350 | 10*M22*1.5 ISO | 335 | 280.8 | 388 |

| JS20F8B12 | 20 | 1850 | 420*220 | >=940 | 150 | 345 | 10*M24*1.5 ISO | 335 | 280.8 | 430 |

| JS25H8B12 | 25 | 1850 | 420*220 | >=940 | 150 | 340 | 10*M24*1.5 ISO | 335 | 280.8 | 474 |

Frequently Asked Questions

1. What makes your hydraulic brake BPW trailer axle a great choice for heavy-duty trucks and trailers?

Our trailer axle is built to meet the highest technical standards and provide optimal performance in even the most demanding industrial settings. With precision engineering and advanced manufacturing technologies, our trailer axles are designed for safety, stability, and exceptional performance.

2. What sizes and capacities are available for your trailer axles?

Our trailer axles come in a variety of sizes and capacities, ranging from 8t-25t. We offer a range of options to meet the specific needs of your industrial application.

3. Can you provide samples of your hydraulic brake BPW trailer axle for testing?

Yes, we’d be happy to provide samples of our trailer axle for testing. We offer our samples free of charge, but ask that you cover the cost of shipping.

4. What is the lead time for manufacturing a new trailer axle?

The lead time for manufacturing a new trailer axle is typically between 20-35 days, once all information has been confirmed. We work quickly and efficiently to deliver your order as soon as possible.

5. What other industrial products do you offer?

In addition to our hydraulic brake BPW trailer axle, we offer a wide range of industrial products, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We pride ourselves on delivering high-quality products at competitive prices, with outstanding customer service and support.

Performance Characteristics of Axle

Axles are crucial components in various vehicles and machinery, providing support and allowing rotational movement. The performance characteristics of axles include load-bearing capacity, durability, and wear resistance. Axles should be able to bear the weight of the vehicle or machinery and maintain stability during operation. Durability is essential as axles are subjected to constant stress and pressure, and wear resistance is necessary to prevent damage and prolong the lifespan of axles.

Types and Characteristics of Axle

There are several types of axles, including straight, drop, and stub axles. Straight axles are the simplest type, consisting of a single shaft connecting the wheels. Drop axles are designed for larger vehicles and feature a drop in the center to lower the ride height. Stub axles are used in trailers and have a pivot point that allows the wheels to turn. The characteristics of axles vary depending on the type and application, but they all share the ability to support and rotate wheels.

Advantages of Axle Made of Different Materials